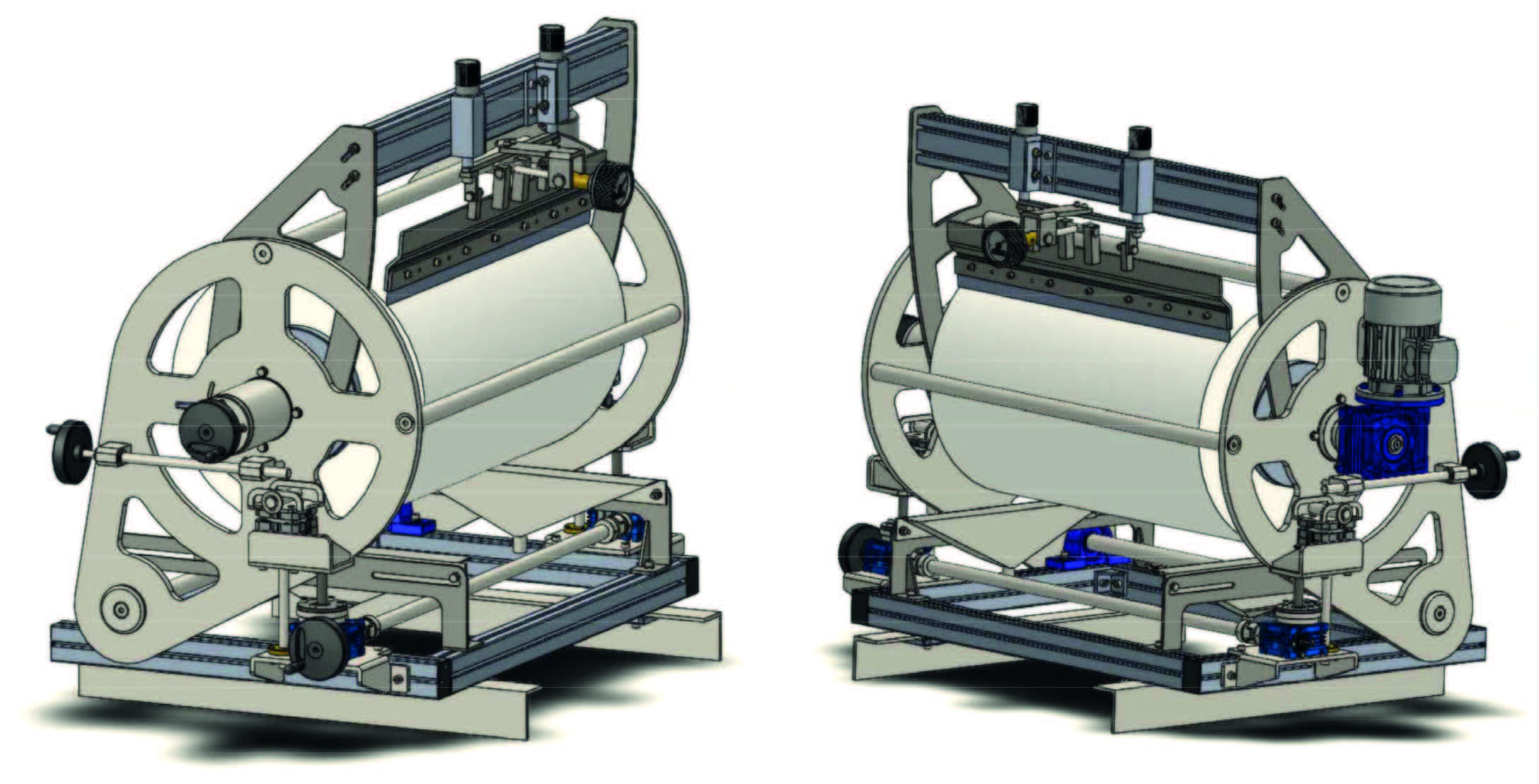

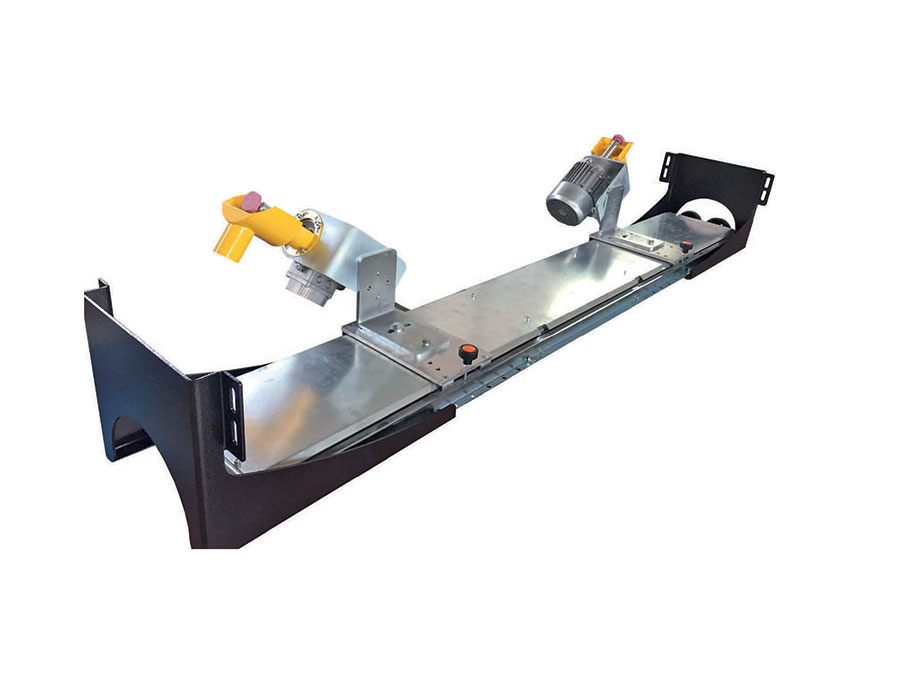

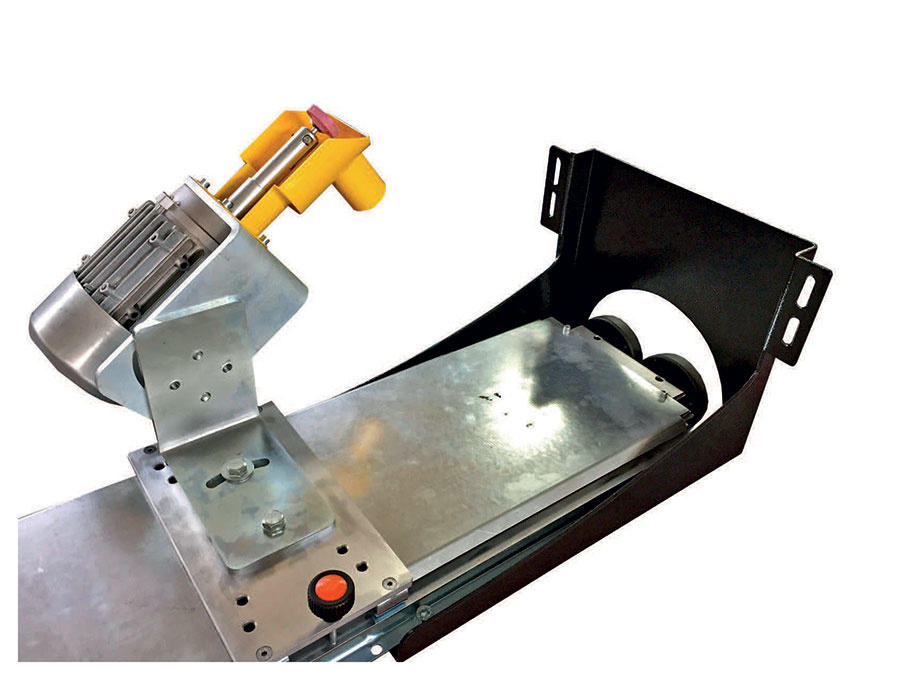

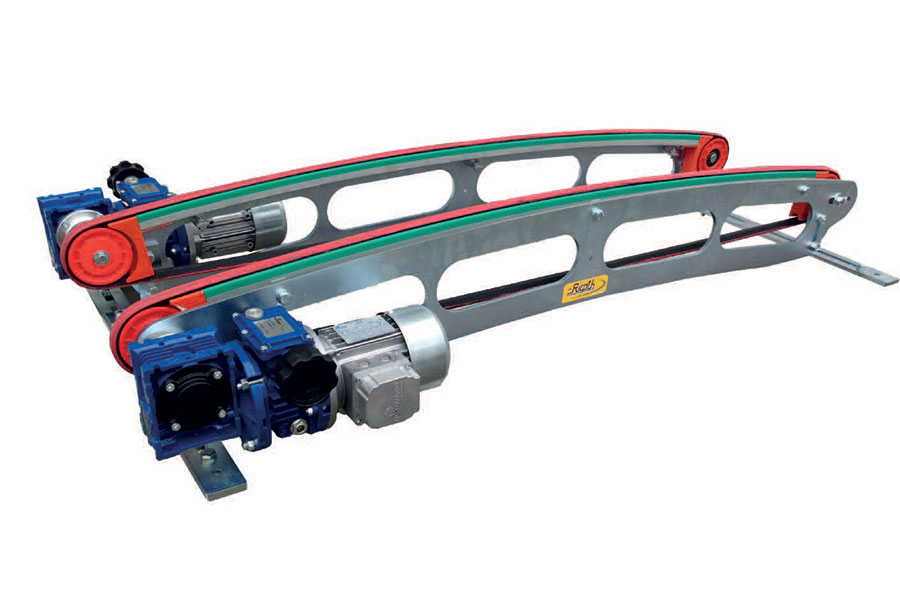

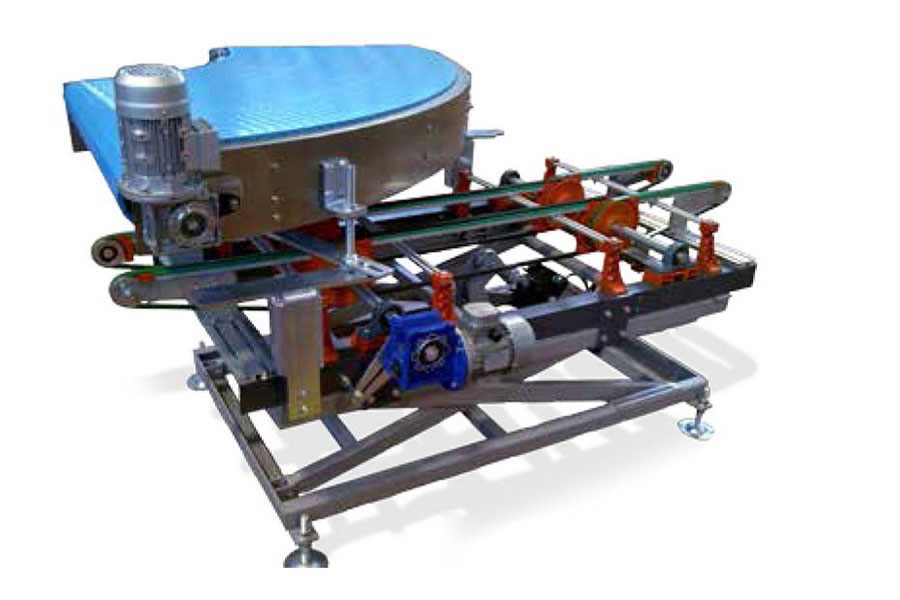

Compenser

It is used to optimize the tiles flow to avoid the production stops and to stock the tiles during the cleaning operations of the digital machines by pulling in case of need and subsequently putting them in empty spaces.

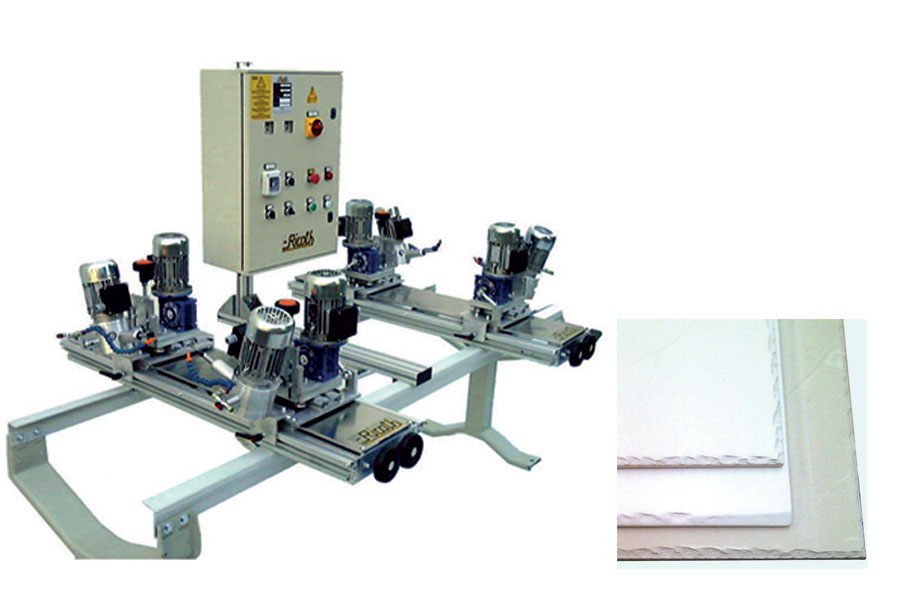

Pre-cottura

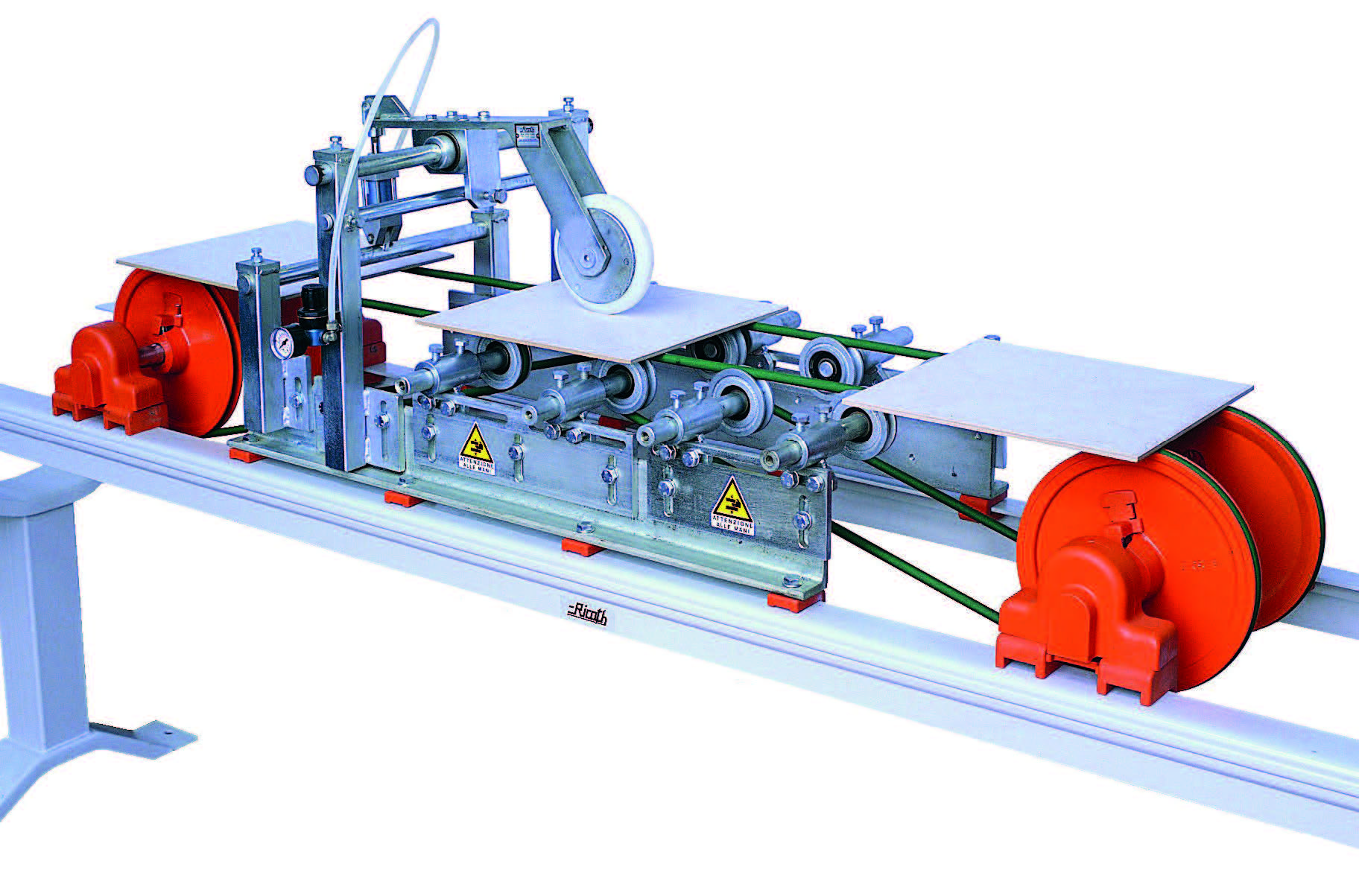

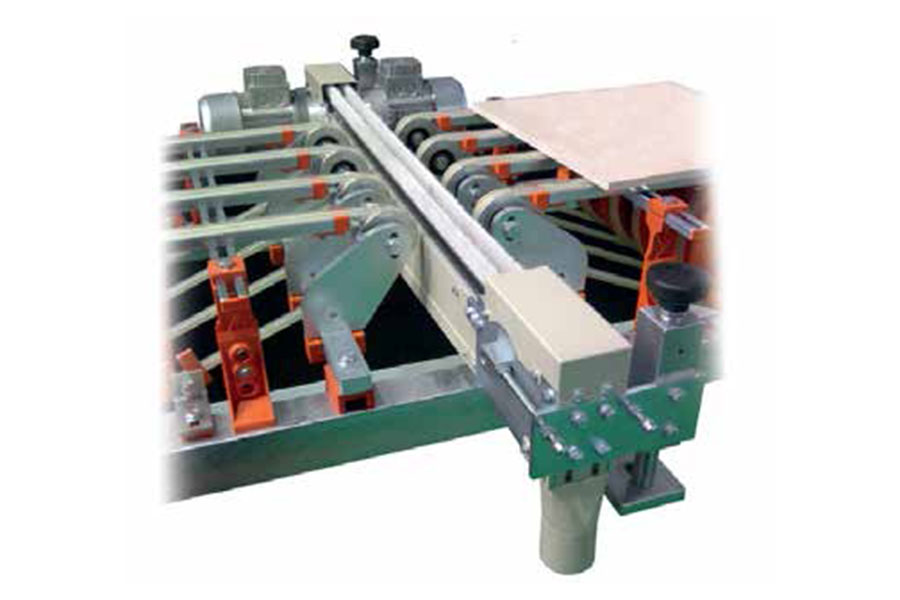

DSP Flat transversal decorating machine

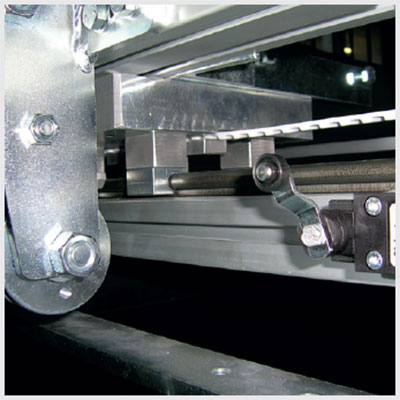

Flat transversal decorating machine composed by a very solid painted steel structure and equipped with 1st choice electromechanical elements studied to reduce to the utmost the production stops caused by damages or breaks.

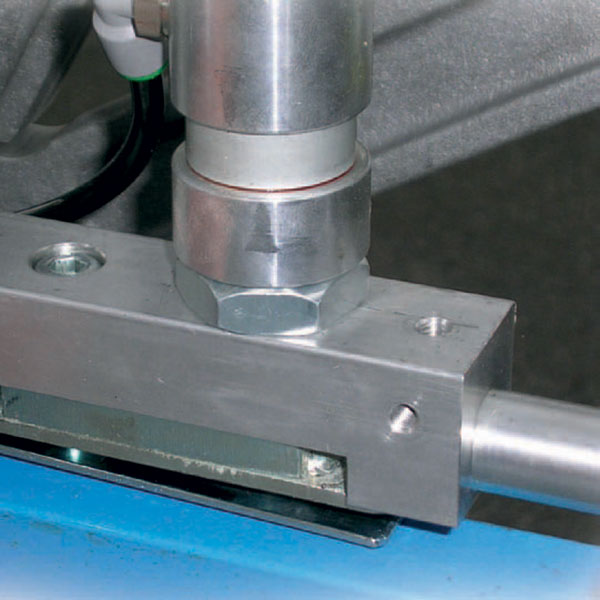

- Powered twist-proof trolley bars

- Pneumatic screen block

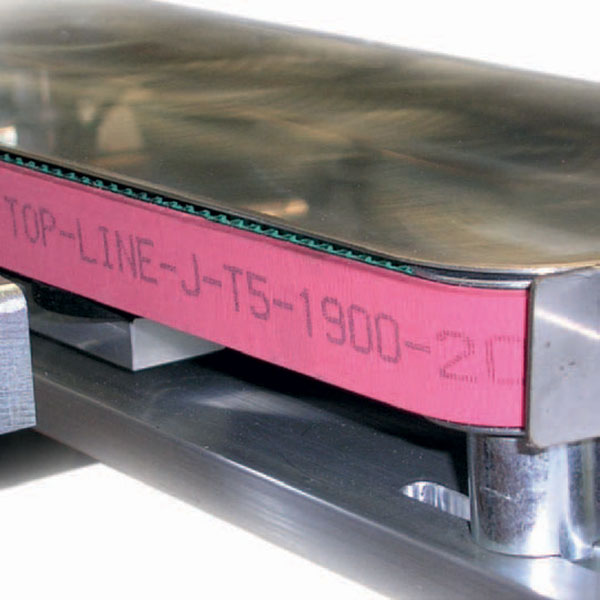

- New generation belts

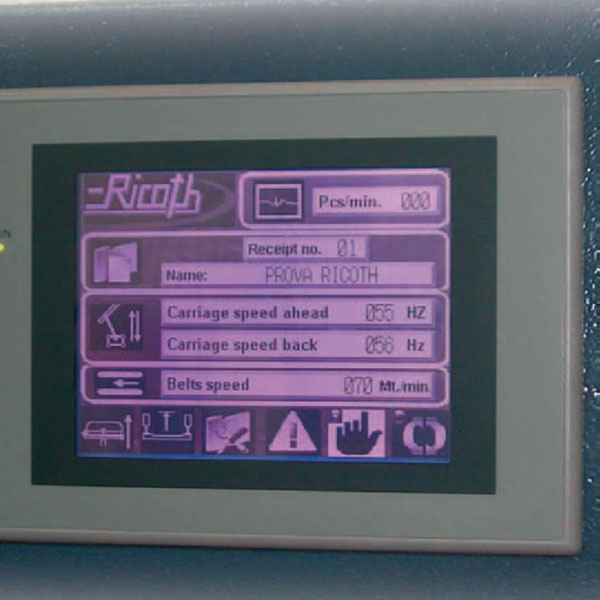

- Touch-screen operator ‘s control

- Total absence of electric cards

Decoration

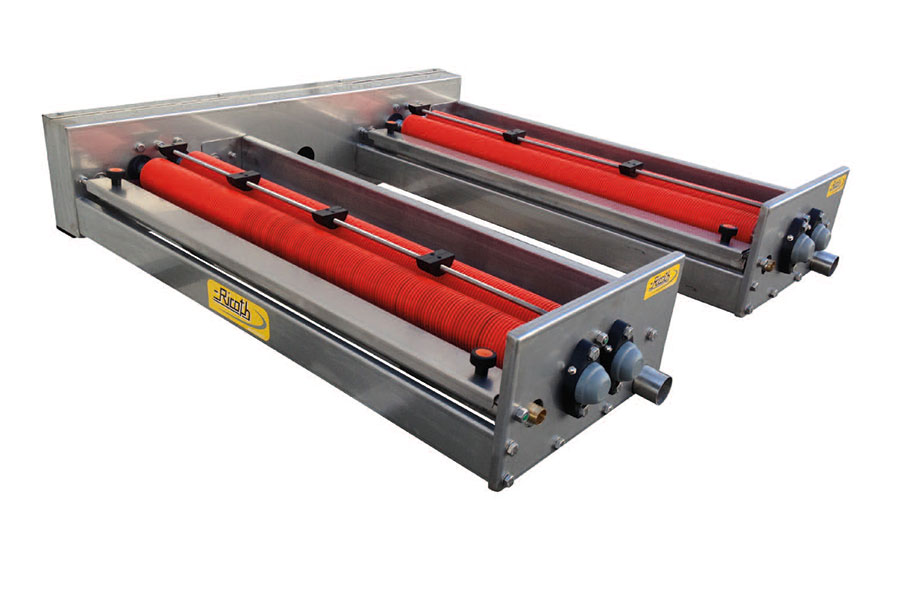

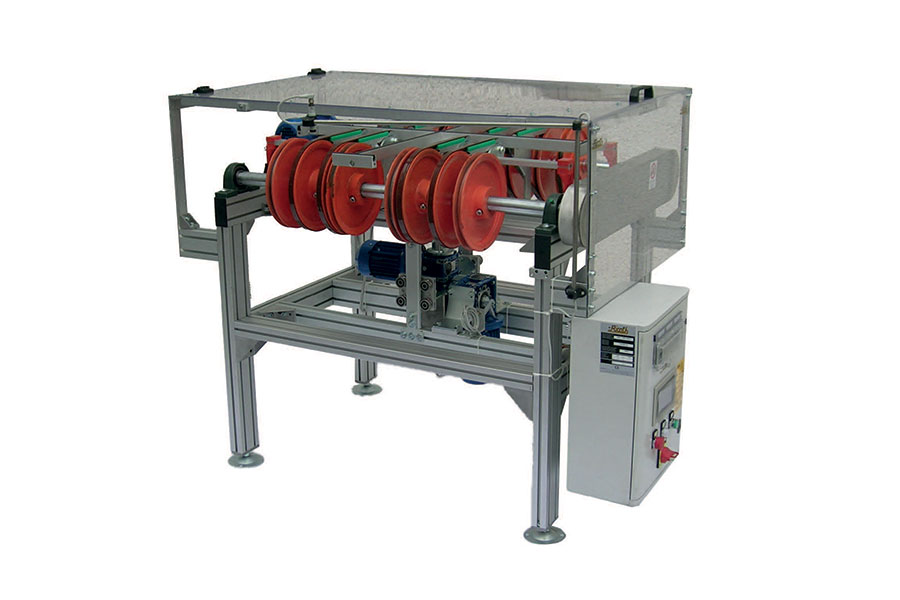

Jet Ice Modular

cod.F0250

Modular system to drop down the tile surface temperature. It exploits an innovative air blowing system with 4 centrifugal electric fans that push the air out at a speed of 160Km/h and a recirculation system that allow to drop down the machine electric consumption and let it work with a medium electric consumption of 8kw. Moreover, JET ICE MODULAR boasts a new powered refrigerating system that allows to take the water temperature to -10°C. This results to be the best compromise to drop down the tile surface temperature instantly eliminating the evaporation..

Decoration

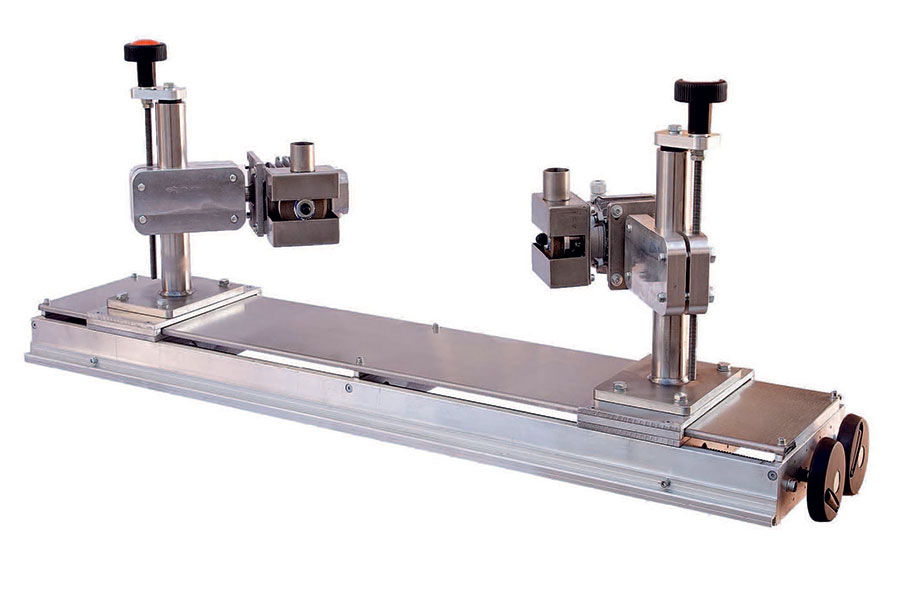

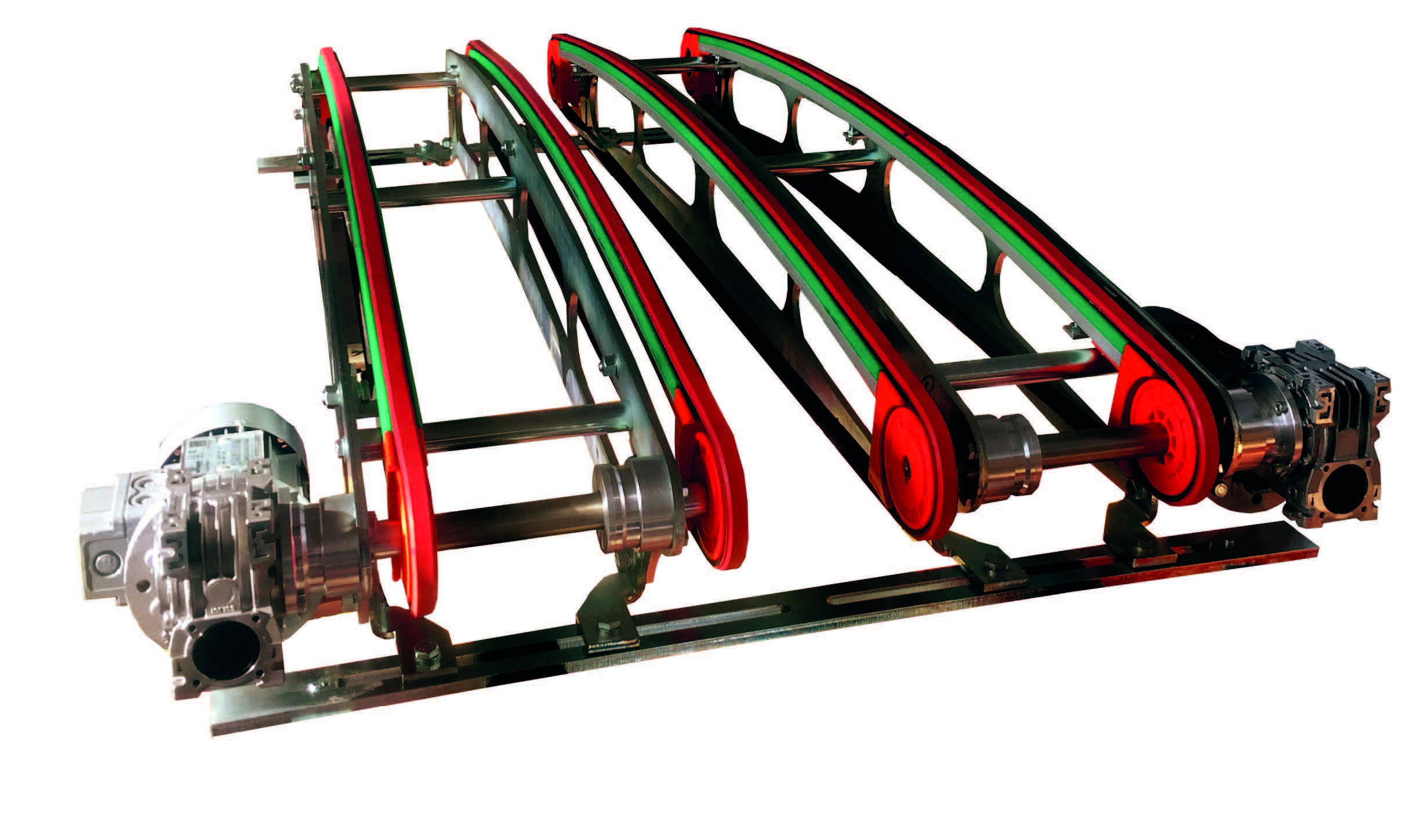

Turning

It turns the tile 90° between two applications. It is available in the following versions: