De-Con / Dvk-Con

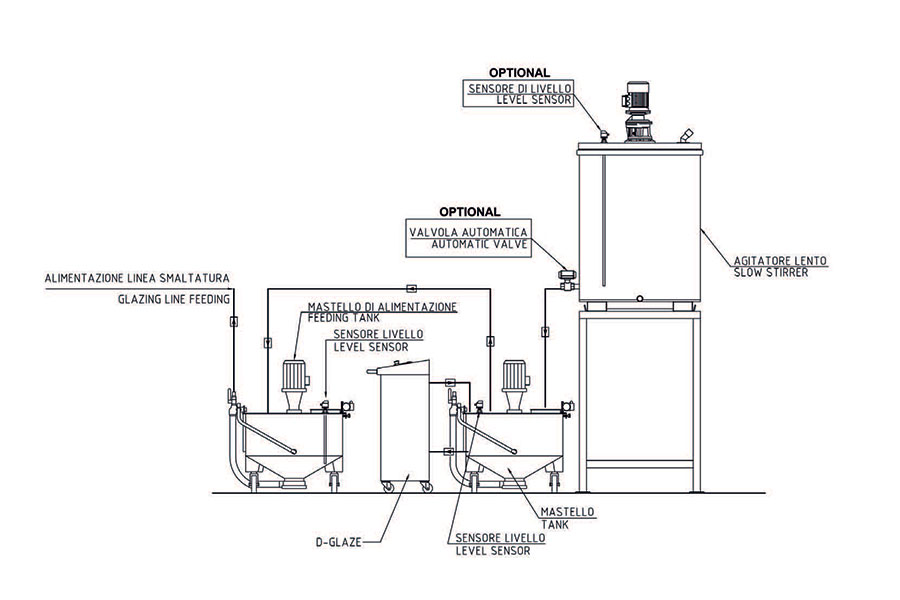

cod.D2280 - DE-CON DISPOSITIVO AUTOMATICO DI CONTROLLO DENSITÀ SMALTO - ENGOBBIOcod.D2286 - DVK-CON DISPOSITIVO AUTOMATICO DI CONTROLO DENSITA – VISCOSITÀ – Kg DI SMALTO - ENGOBBIO

“DE-CON Automatic Density Control” GLAZES DENSITY CONTROL DEVICE

“DE-CON” Can be used on waterfall machines, bells, airless systems, disk cabins, spray-guns.

This machine permits to keep constant the set density.

The main advantages of “DE-CON” are:

- It avoids the waste of glaze and tonality changes with considerable time and money saving.

- Complete feeding automation and density monitoring in real time of the glaze sent to the machines.

- Elimination of the delays due to the manual glazes preparation and quality increase of the final product thanks to a continuous control.

- Elimination of hard works for the operators who will not enter into direct contact with glazes or other products potentially harmful.

- Possibility of managing 2 additional additives.

Glazing

Power-bell 200x200 - 2000x2000

cod.C3045

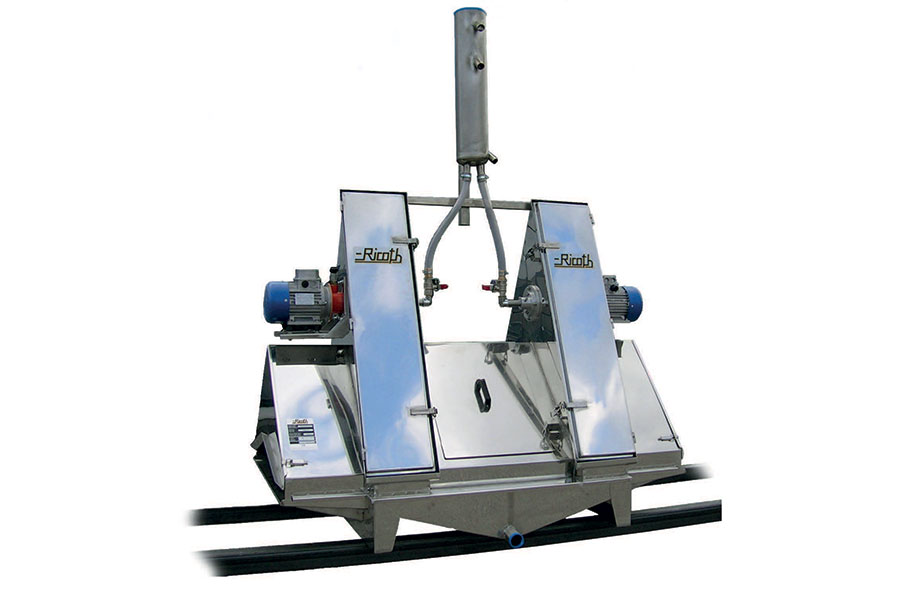

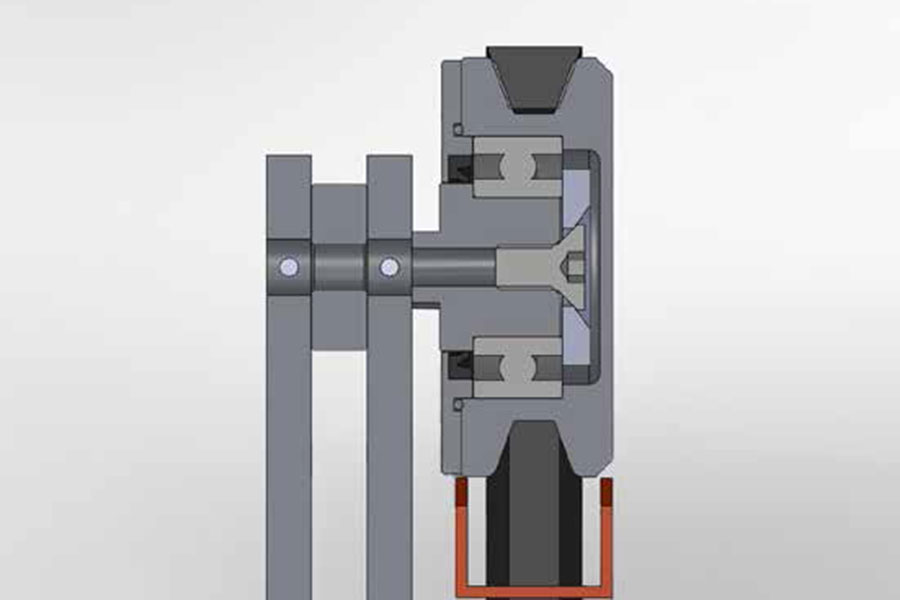

PRESSURE GLAZE APPLICATION SYSTEM

Waterfall application machine made of stainless steel aisi 304 with internal chamber coated with anti-abrasion rubber. The machine has been studied for the application of engobes, glazes, glazes with micro-grains and vitreous crystallines. It is fed by a stirrer tank with pump. The machine is equipped with a filter at the entry with bubble-proof system and manual venting to eliminate the air inside the chamber. It is complete of electric control panel (control flux) that controls the capacity flow and by inverter regulator it keeps constant the weight parameters that have been set. Pump for feeding of “power-bell” machine. It is available also in the version for high viscosity glazes and glazes with micro-grains.

Glazing

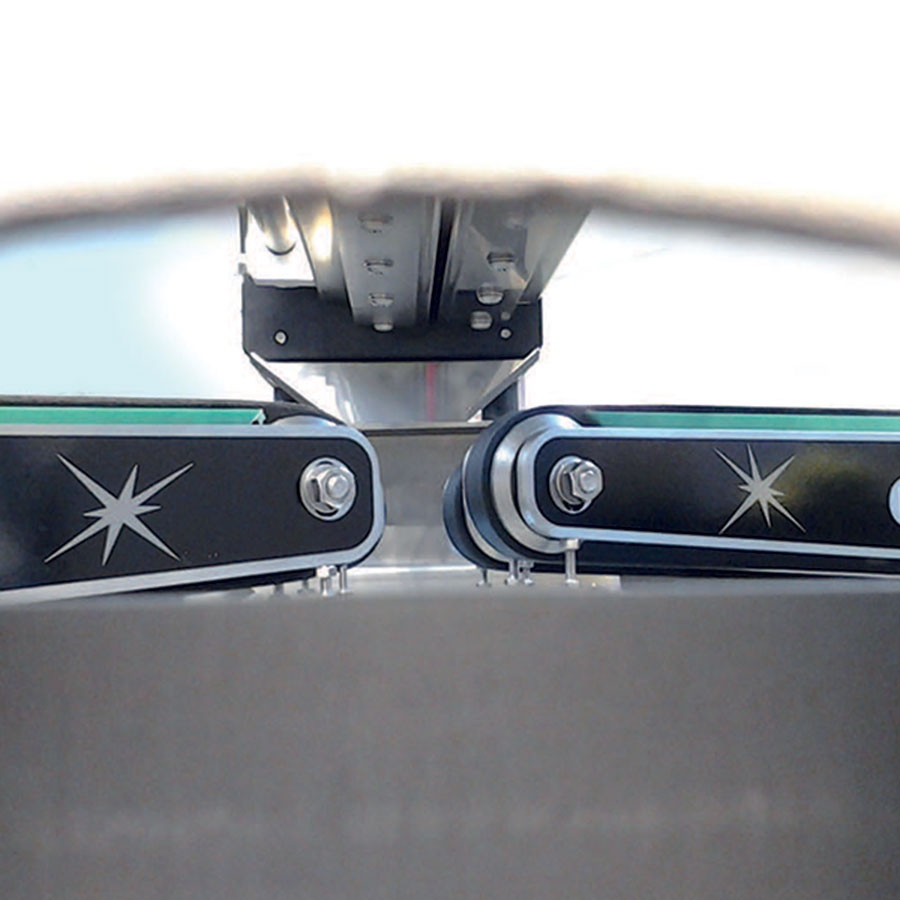

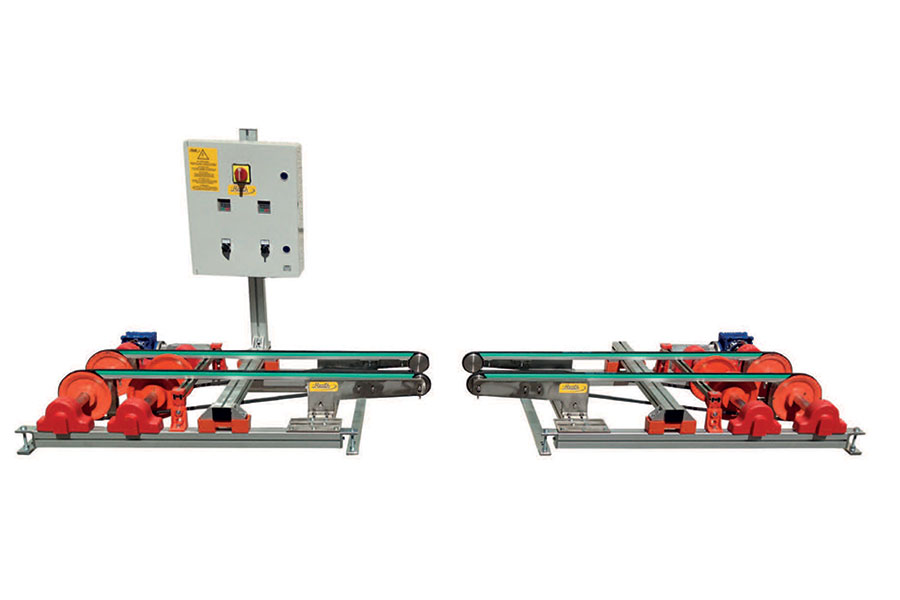

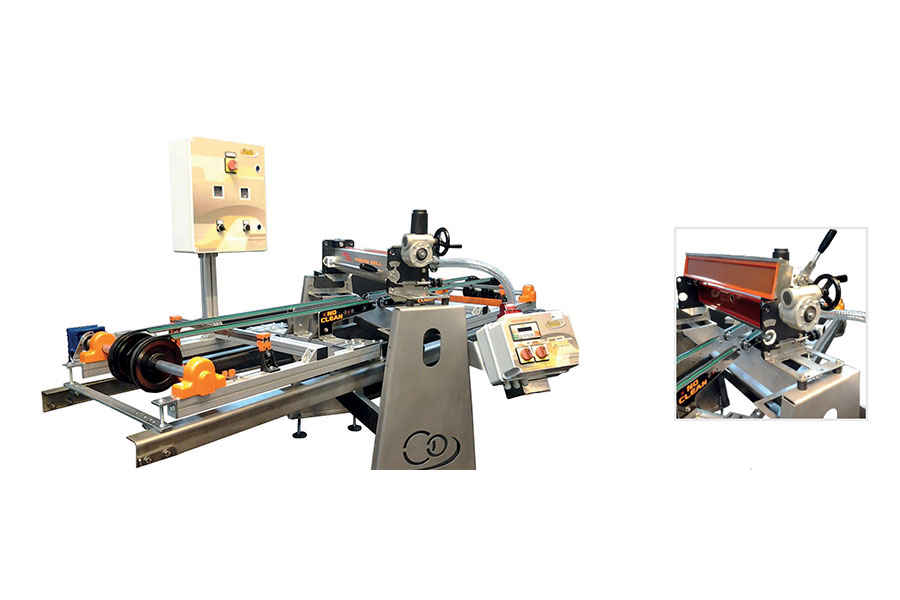

No-Clean

cod.C3054

Device for the interruption of the conveyor belts under the application of glaze, engobe done by bell or “power-bell”. This application permits to avoid the transport of the glaze on the belts that consequently dirts the surface under the tile. The machine is controlled by two geared motors synchronized by inverter.